- Overview

- Product Parameters

- Product Description

- Mould Production Process

- Associated Products

- FAQ

Basic Info.

Product Description

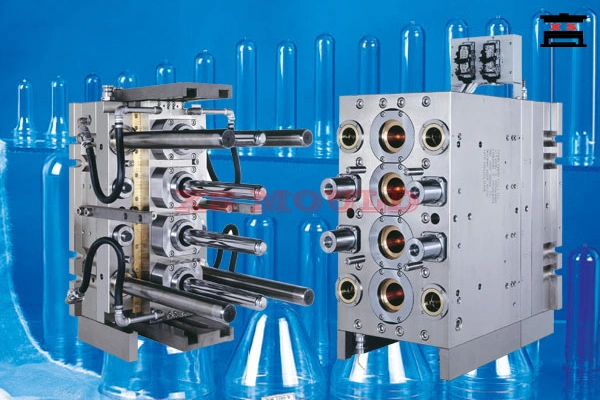

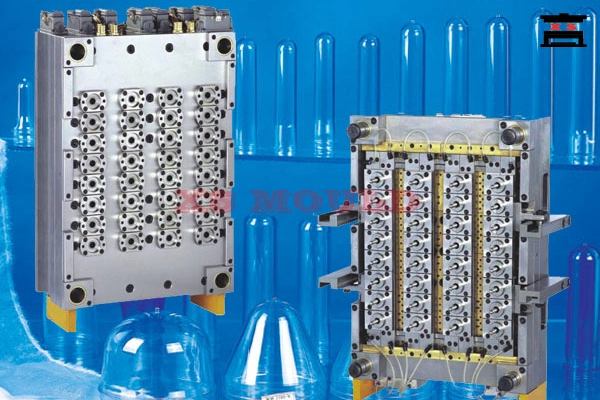

| Mould name | PET Preform Injection Mold Maker |

| Mould cavity number | multi cavity |

| Mould runner systerm | hot runner |

| Mould T1 Time | 25-60days |

| Mould package | exported wooden case |

| Mould Life | 1million shots |

| Mould core&cavity steel | S136,3Cr13,4Cr13,etc |

| Mould base steel | S45C,S50C,P20 |

Taizhou Huangyan Xiong Shi Plastic Mould is located in Taizhou,China since 2009. We focus on injection mould of plastic packages,including PET preform molds and various plastic cap moulds.After decade years effort, It has steadily developed into a modern enterprise specialized in manufacturing various specification of PET Preform mold and cap mould. With reasonable price, reliable quality and excellent service, we highly praised at home and abroad customers. Products are exported to Russia,Australia,Egypt,Ethiopia,Bangladesh, India, Malaysia,Cambodia and other countries and regions. Its widely used in the water,beverage,edible oil, food, cosmetics,washing supplies and other packaging industry, etc. The company inherits the responsibility throughout all the time, the quality originates from the responsibility idea to create the valve for the customer, everything starts from the production details.

There are two different types hot runner widely used for preform molds - valve gated hot runner and thermally gated hot runner.

Thermally gated hot runner use rod heaters and rod heaters were pluged into mold from one side to another side. In order to easily assemble and maintain heaters, often there is no cover on the mold heaters insert side. So we can see the heaters and wires from preform mould one side. Thermally gated hot runner temperature controller one zone control one rod heater. With this reason thermally gated hot runner temperature controller have less controller zones compare with valved gated hot runner temperature controller.Valved gated hot runner use ring heaters and contain one manifold plate. We only can see the hot runner socket on the mold. Valved gated hot runner preform every heater need to be controlled by sperated temperature controller zone. Compare with thermally gated hot runner temperature controller, valved gated hot runner temperature controller have more controller zones.

§ Type of gate vestige

There are total three types of gate vestige for different hot runner gate preforms - long length vestige, short length vestige and flat little length vestige.The vestige difference is caused by the different hot runner nozzle design. Long length vestige preform hot runner nozzel without heater or very little length heater. So the gestige length is very long. Need to use preform gestige cutting machine to trim the preform, then can go on the strech blow molding with these preforms.

There are two ways to separate the hot melt coming through the hot run-ner from the cooled preform: thermal and mechanical. Thermally gated hot runners are most prevalent in one-stage while it is the other way around in two-stage injection molding.In a thermally gated hot runner the break point between the hot and cold melts is controlled by temperature alone. As seen in above picture the tempera-ture difference between the cold cavity and the hot melt is substantial at around 255°C (491°F). A suitable insulation made from stainless steel or other material with insulating properties separates the two sections. When the machine ejects the preforms the melt breaks at the point where thecold gate vestige connects with the hotter material inside the nozzle. This material is already partly cooled down and so has a higher than melt vis-cosity. This prevents it from seeping into the cavity or lead to "stringing,"a common defect where small strands of PET from the melt stream are pulled out with the preform during ejection. An air gap may also assist in the separation process .

In the plastic package industry, apart from PET preform molds,we are experience of making lots of plastic cap moulds as well. For more details,you can check our plastic cap mould group

Q1: Are you mould factory or mould trader?

Answer: We are speciallized plastic injection mould factory locacted in Taizhou, China

Q2: How to visit your company?

Answer: Our city is near Shanghai, When you arrive at Shanghai airport, you can by high speed train from Shanghai Hongqiao train station to Taizhou Station. We will pick you up from train station.

Q3: What's the payment term?

Answer: TT, 40% advance payment, balance amount be paid before mould shipment.

Q4: How can I achieve satisfied product design?

Answer: In the begining, you may only have a rough product idea or rough product drawing, we are capable to make initial design and imporove the rough product drawing till to completed and satisfied drawing through effective mutual communication. Finally we will figure out the whole project secessfully.

Q5: How about delivery time?

Answer: The T1 trial time normally 25-70days depends on different mould. After trial samples are approved by client, moulds can be shipped within one week.

Q6: What are the services do you offer?

Answer: We offer lots of services to our clients,including product drawing improvement, mould 2D&3D design,prototype samples, mould flow analysis, DFM report,after-sale service,etc